A worldwide ICT company tracks and manages the location of every client’s servers and other high value IT assets automatically, and can report on their location at the click of a button. Read the Case study and learn how Brady Corporation helped the customer to automate datacentre inventory tracking

Discover Brady’s complete RFID solution >>

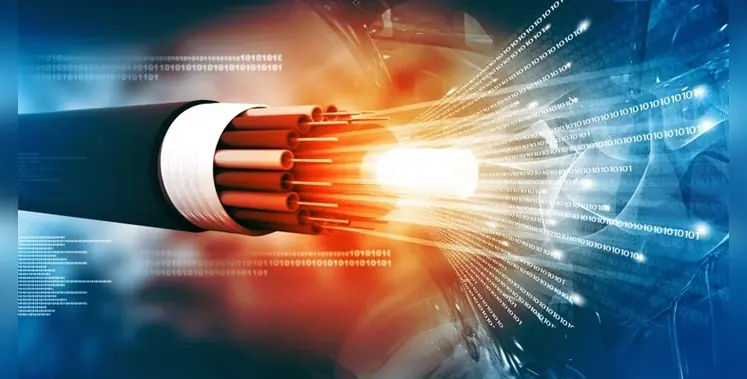

A worldwide ICT-company needed to automate how their servers were tracked and managed. With thousands of high value ICT assets in play, the ability to report without error on real-time asset whereabouts proved essential for both commercial success and compliance. In addition, the company was looking for ways to enhance cable maintenance intervention speed and accuracy.

Solution: Custom on-metal UHF RFID and NFC labels

Custom, passive RFID labels on every asset, combined with fixed scanners at all datacenter exits provide accurate, real-time tracking. Print-and-programme printers in a central location enable the company to label any new assets immediately with reliable, custom RFID labels to maintain a complete overview at the click of a button

Brady can customise its RFID labels entirely so they can fit the needs of any customer. The L-2588-25C on-metal UHF RFID label with a 3 metre read range can be supplied to label all servers and flat surface assets. The label is equipped with an insulation layer to avoid interference between metal surfaces and its RFID antenna.

The label is constructed using a reliable polyester that will stay attached and remain legible in datacenter environments. Scanner gates were set up at all exits and entrances to help track server movement from a central location. Captured data are automatically added or removed from datacenter inventory lists.The UHF RFID labels are printed and encoded on site using specialised UHF RFID print-and-program printers. These enable the ICT-company to equip each RFID label with a unique number for automated, accurate tracking of any labelled asset.

A custom HF RFID, or NFC, flag label can be added to identify cables with a smartphone or NFC pin point reader in close proximity. It enables datacenter technicians to quickly verify which cables to replace, to switch equipment smoothly, and to access complete source & destination information as well as cable history. In addition, Brady offers NFC enabled printers to encode and print HF RFID, or NFC, labels.

Results: Automated inventory management with custom RFID labels

Relevant asset locations, time-stamps, and other data are available in real-time at the click of a button. Staff no longer have to manually count assets and can assess a site’s entire ICT inventory in a couple of hours, instead of weeks. The data also enable the company to prevent errors in asset movement through automatic alerts generated via the supporting software. This increases overall efficiency and decreases labour cost.

An RFID solution tailored to the industrial environment

An RFID solution tailored to the industrial environment

Brady leverages all of its knowledge and capabilities to provide complex industries with unique RFID labelling solutions tailored to specific applications and environments. Customisable RFID label components include RFID antennas, chips, optional sensors, adhesives, industrial grade label material, label shape and colour, label preprints and preprogramming. The high level of customisation enables RFID read range modification, applications that require abrasion, chemical, oil or outdoor resistance, and applications both on- and off-metal surfaces.

Brady can provide a complete solution that includes print-and-programme RFID printers and scanners for custom RFID labels. Software can be provided and integrated to manage RFID driven processes, which can include proximity detection, maintenance or installation guidance, shipment control, warehouse forklift automation or simple item counting at specific scanner gates.

Brady specialists are ready to assist you in finding the right combination of RFID products to solve your identification need.

Find out more about Brady's complete RFID solutions here