Along with high-performance Class EA/Cat. 6A copper cabling, a new test procedure has also been launched for the corresponding network components: the re-embedded test.

p>Along with high-performance Class EA/Cat. 6A copper cabling, a new test procedure has also been launched for the corresponding network components: the re-embedded test.

Swiss cabling company R&M explains the significance of this test procedure for the operating reliability of data networks in a current White Paper.

Swiss cabling company R&M explains the significance of this test procedure for the operating reliability of data networks in a current White Paper.

The re-embedded method enables signal transmission in RJ45 plugs to be tested more quickly and precisely than in the de-embedded test the industry used up until now. The new test process is described in the standard IEC 60512-27-100. Manufacturers such as R&M carry out these tests regularly, especially with new advances such as Cat. 6A. The purpose of testing is to prove that plug and connection module transmit the signals perfectly. Among other things, testing determines how interference factors such as crosstalk affect signal transmission.

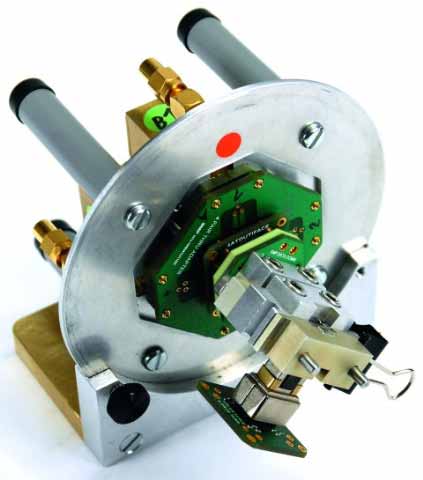

Testing is also meant to show that a given manufacturer’s products deliver the expected performance even when combined with another manufacturer’s products. Until now, you had to conduct elaborate series of tests and test each connection module with twelve individual test plugs. In the high-frequency applications involved with Cat 6A, the test setup was subject to error. In the new re-embedded test, you determine the results strictly mathematically based on 14 simulated plugs. Measurements are now conducted directly on the rigid test head of a network analyzer, so that interferences that may arise, for example from moving cables, can be excluded. Overall, the re-embedded method improves measurement quality and allows more precise conclusions to be drawn about the fluctuation and limit behavior of a plug or connection module.

R&M warns customers against viewing results from a re-embedded test as proof of quality in themselves. Dominik Schweizer from the R&M Engineering Test Lab in Wetzikon: “The re-embedded model is an excellent test method. However, the crucial thing is to have the components strictly satisfy the specifications for the pertinent standards such as ISO 11801 and IEC 60603-7-41/51.”

Cabling specialist R&M tests its own products according to much more stringent standards than those recommended by the standard-setting bodies. R&M does make references to the re-embedded model, however. In addition, R&M also tests older component generations such as Cat. 5e and Cat. 6 using the new processes in order to improve them where necessary and to guarantee full backward compatibility of the connection equipment. Dominik Schweizer: “The re-embedded process should be used on all component generations. That is reasonable from the standpoint of standardization and also with regard to obtaining uniform, physically correct data.”